Bitumen, also known as asphalt, is a sticky, black or brown hydrocarbon material that is found naturally or as a by-product of petroleum refining. It is used in a variety of applications, including paving roads, waterproofing roofs, and sealing cracks.

Diverse Applications of Bitumen

The versatility of bitumen translates into a wide range of uses:

• Road Construction: Bitumen serves as the key ingredient in asphalt, used for building and maintaining roads, highways, and other transportation surfaces.

• Waterproofing: Leveraging its water-resistant nature, bitumen is employed in waterproofing roofs, foundations, and other structures.

• Protective Coatings: Bitumen acts as a protective shield for metal surfaces, safeguarding them from corrosion and rust.

• Other Industries: Beyond these core applications, bitumen plays a role in various products like drainage pipes, roofing materials, and even rubber products.

Iran boasts a diverse range of high-quality bitumen products suited for various applications, making them highly sought-after in the global export market. Here’s a breakdown of the different types of Iranian bitumen commonly exported:

Different Types of Bitumen Based on Modification:

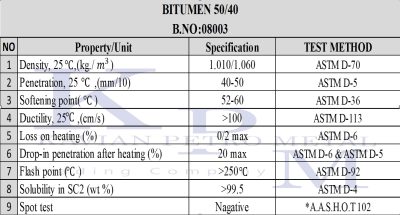

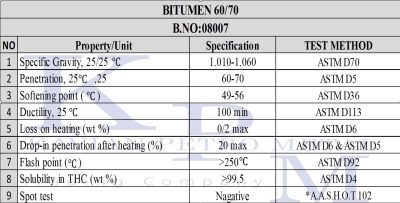

• Penetration Grade Bitumen: This is the most widely used type, categorized by its penetration depth, a measure of hardness. Common grades include 60/70, 80/100, and 90/100. They are ideal for road construction and waterproofing due to their varying degrees of flexibility and temperature resistance.

• Performance Grade (PG) Bitumen: Engineered for specific performance requirements, PG bitumen grades like PG 64-22 or PG 76-10 offer superior durability and stability in extreme temperature conditions. They are often used in pavement construction projects in regions with significant temperature variations.

• Viscosity Grade (VG) Bitumen: Classified by their viscosity (thickness) at specific temperatures, VG bitumen grades like VG-10 or VG-40 cater to applications requiring optimal performance at high temperatures. They are particularly suitable for use in hot climates or for applications where bitumen needs to remain fluid during processing.

Different Types of Bitumen Based on Processing:

• Cutback Bitumen: This type is produced by adding solvents like kerosene to regular bitumen, making it easier to apply at lower temperatures. Cutback bitumen comes in rapid, medium, or slow curing varieties, depending on solvent evaporation rates. They are often used for patching, tack coating (bonding layers), and cold weather applications.

• Oxidized Bitumen: This variety undergoes an air-blowing process to enhance its adhesive properties and resistance to aging. Grades like 75/30 or 90/15 are commonly used in roofing membranes, pipe coatings, and industrial applications where strong adhesion and weatherproofing are crucial.

• Emulsion Bitumen: Here, bitumen is suspended in water with the help of emulsifiers, creating a water-based solution. This eco-friendly option offers easier handling, lower application temperatures, and reduced solvent emissions. Emulsion bitumen grades like CRS (Cationic Rapid Setting) or CSS (Cationic Slow Setting) are used for chip sealing (applying gravel to asphalt) and pavement rejuvenation.

• Polymer Modified Bitumen (PMB): This type incorporates polymers into the bitumen for enhanced elasticity, fatigue resistance, and durability. PMB finds application in high-traffic roads, airport pavements, and bridge decks where superior performance under stress is essential.

Specifications of Iranian Bitumen

Iranian bitumen is known for its high quality and competitive prices. Iran is a major exporter of bitumen, and the country produces a variety of grades to meet the needs of different customers.The following are some of the specifications of Iranian bitumen:

• High penetration: Iranian bitumen typically has a high penetration depth, which makes it more flexible and easier to work with.

• Low sulfur content: The low sulfur content of Iranian bitumen makes it less susceptible to aging and cracking.

• Good adhesion: Iranian bitumen has good adhesion properties, which means that it bonds well to aggregate and other materials.

By understanding these different types of Iranian bitumen and their properties, you can identify the most suitable option for your specific needs and project requirements.

Packing; Steel Drum, Jumbo Bags, Flexitank, Bulk,

Origin: IRAN, IRAQ, BAHRAIN

Producers: JEY, PASARGAD, mini Refineries in Shiraz, Tehran, Bandar Abas, Tabriz

Payment Terms: 30% cash in advanced & 70% against documents – with LC

Delivery Terms: FCA, FOB, CIF, CFR

Keywords: Iranian penetration grade bitumen, bitumen for road construction, Iranian viscosity grade bitumen, bitumen for hot climates, Iranian cutback bitumen, bitumen for cold weather, Iranian oxidized bitumen, bitumen for roofing, Iranian emulsion bitumen, bitumen for chip sealing, Iranian polymer modified bitumen, bitumen for high-traffic roads.

BITUMEN 50 40

BITUMEN 50 40  BITUMEN 50 70

BITUMEN 50 70  BITUMEN 60 70 (2)

BITUMEN 60 70 (2)  BITUMEN

BITUMEN 60 70 BITUMEN 85 100

60 70 BITUMEN 85 100

Reviews

There are no reviews yet.